- …

- …

Cable Making Machine Manufacturer

Our wire machines sells more 40 countries.

Exported 130 cable factories.

Established since 1983.

What Wire Machines We Produce?

Full manufacturing process of cable and wire for Beyde Customers.

Metal Rod Drawing

The wire drawing process is the first step of wire rod production. Through copper, aluminum and related alloy rods, the cross-sectional area can be reduced and the shape can be changed through the wire drawing machine.

Conductor Stranding

Stranding is the process where a particular number of copper, aluminum or steel wire conductors are joined together while winding them round a common axis. s the most important part of cable manufacturing.

Insulation Wire Cabling

The insulated cable is now prepared. we just need to cabling one or more muitl strands of wires together. Meanwhile use filler to ensure the finished cable in a shape of round. meahwhile it can make taping and armoring production.

Extrusion Process

It is most important manufacturing process. the wire or conductor is passed through an cable extruder, where the coating of plastic or other insulating material is applied. like PVC,PE,LSZH,etc.

A manufacturer integrating industry and trade for cable and wire

We offers machines for producing different cable and wire. such as stranding, rotating, extruding and coiling machines.

We are equipped with advanced cable and wire making equipment such as special tools. BEYDE has a global advanced cutting, bending,

annealing and dynamic balance machine.

We provides different accessories for customers to choose freely, such as Siemens, Yaskawa, NSK, SKF, Schneider and other international well-known brands.

At the same time, we also provide high-quality and cheap Chinese accessories, such as HRB, Chint, Inovance, Sinee, etc.

If customized, we can also meet your requirements.

Customized Cable Machinery for Our Customers:

We have the manufacturing ability to customize any cable and wire equipment. We can process and manufacture cables according to the type, size and specification what you need. Our engineers customize your order with the following services and processes:

Efficient stranding&rotating equipment for copper, aluminum conductors and steel wire ropes.

Fully automatic extrusion equipment for insulating jacket.

Comprehensive cable factory building and construct services.

Fast installation, training and turn-key service.

Ultra long quality warranty period.

Lifelong free technical guidance service.

Low cost spare parts supply service.

Accurate and fast logistics assistance service.

Main Cable Making Equipments

Competitive And High Quality Cable&Wire Machinery for you

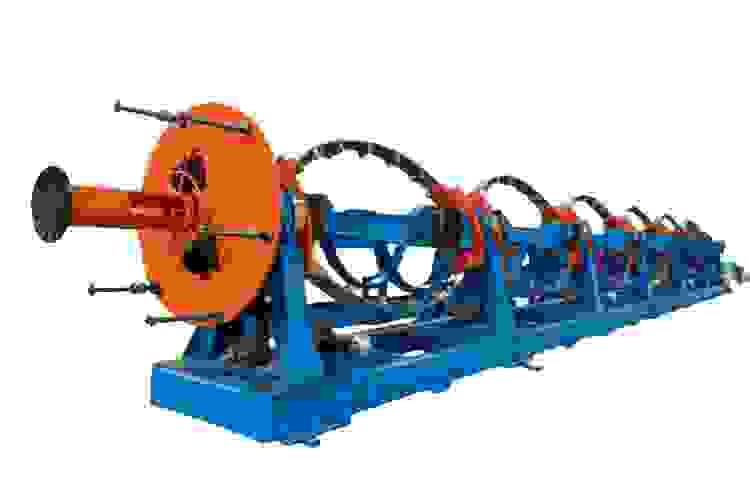

Rigid Frame Stranding Machine

BEYDE independent motor driving type rigid stranding machine is mainly used for the stranding of circular or sector copper-aluminum conductors. Also necessary equipment for power cables.

Core Laying-up Machine

High speed 50RPM cradle laying-up machine is mainly used for the cabling of power cables or control cables from 10-300sqmm, meanwhile can lay-up round or sector cables with filling, taping and armored function.

Tubular type Stranding Machine

Our professional tubular closer is used for twisting steel wire rope with in-line pre-stretching. also calls tubular stranding machine to twisting copper, aluminum and insulated wire.

Planetary Stranding Machine

Planetary type stranding machine with 100% back-twisting fuction, it can be used for twisting copper, aluminum and steel wires, and can also be used for cabling of insulated wires. BEYDE also provides such professional wire rope equipment.

Bow Type Laying-up Machine

Bow type laying up machine working with back twist movement to lay-up from 3 to 6 cores of ABC aerial cables, control cable or power cable from 10-120sqmm.

Drum Twister Line

Our high speed drum twister line is used for cabling of low and medium voltage conductors, screening and armoring of high voltage conductors, upto 630sqmm round or sector type (MILLIKEN).

Steel Wire Armoring Machine

The machine with 100% back-twist is mainly used for inner or outer layer steel armoring or copper wire screening for the cables, as well as twisting AI and Cu conductors, control wires, rubber insulated wires, meanwhile with metal taping unit.

Cable Sheathing Extruder

Cable extruder is a manufacturing process used to shape molten plastic. CAPSTIAN provide kind of extruder, like PVC, PE, LSZH, Silicone rubber, teflon extrusion line. automatic operating and high speed.Our Machinery Application for Different Industries

- Power cable industry. Our machinery can produce all kinds of wires and cables, such as LV, MV and HV for civil or industrial purposes.

- Automobile industry. BEYDE provides professional equipment for the production of new energy vehicle wires and brake wires.

- Steel wire rope industry. We have professional wire rope equipment for you, which can meet the needs of fishing rope, Dyform, crane rope and so on.

- In addition, I am also involved in the medical and military industries.

Why we are Trusted by 500+Clients?

Our cable machinery has brought many benefits to many industries, enterprises and projects. The following are our advantages

Affordable and Fast Production Speed:

We can quickly produce different cable stranding and extruding machine. CAPSTIAN offers speedy production while assuring high quality. More than 200 employees, 30000 square meters of plant area, 200 orders per year.

Excellent Performance and Long Working Life:

Using international advanced manufacturing equipment, we can easily produce high-performance and durable cable machinery, and promise super long warranty.

Famous Brand Accessories and High-quality Raw Materials:

We use international famous brand electrical appliances, bearings and other accessories, such as Siemens, NSK, Schneider And the fuselage frame with higher strength is precision machined

Stranding & Rotating Machines

We provides to you with professional cable, wire rope stranding and rotating equipment such as:

We also provides cable auxiliary machinery, like pay-off&take-up, haul-off&caterpillar, taping unit, rewinding machine, armored machine etc.

Extruding & Coating Machines

BEYDE offers highly intelligent and efficient cable sheath extruding and coating equipment such as:PVC,PE,LSZH Sheathing MachineSilicone Rubber Extruder MachineTeflon Wire Extrusion LinePower Cable Extrusion LinePhysical & Chemical Foaming ExtruderDouble Layer Co-extrusion MachineTriple Layer Co-extrusion MachineXLPE Cable Coating MachineAutomatic Coiling MachineWe also provides auxiliary machinery of extruder, like sparker tester, diameter tester, pre-heating, wire accumulator, cable printer etc.Our Customers from all World

This is really a part of our customers. Our customers cover more than 300 cable enterprises at home and abroad, involving energy, trade, government agencies, etc.

The longest service of the machine is 35 years, which has been fully affirmed by customers.

Real Factory Display

1. 300 workers

2. 30000 square meters of production workshop

3. Bachelor degree up to 80%.

4. Annual export of 300 sets

5. High precision and cutting-edge processing equipment

6. Strict quality control

Contact Max Xu at any time!

Best wire machine, Best service, Fastest delivery

FAQ

What can I do for your requirement about cable and wire manufacturing?

What application of Our Cable and Wire Machinery?

How long time of Beyde' wire machine warranty?

How to do if I don't know what machines for my wire?

Do you provide turn-key service for customer new cable building factory?

Is the Beyde trading a real cable and wire equipment manufacturer?